|

|

|

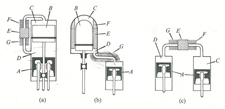

Figure 1: three basic arrangements by which most type of Stirling engines may be classified:

(a) Piston-displacer in the same cylinder

(b) Piston-displacer in separate cylinders

(c) Two-piston machine

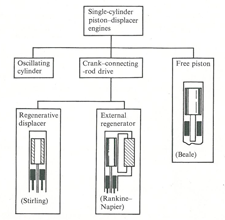

Figure 2: alternative arrangements of the single-cylinder piston-displacer engine

The elements of a Stirling engine include two spaces at different temperatures having volumes that can be varied cyclically and which are connected through a regenerative heat exchanger and auxiliary heat exchangers. These simple elements can be combined in a surprisingly wide range of mechanical arrangements.

The key identifying feature of any regenerative system is the manner in which the flow of working fluid is controlled. There are two possibilities; flow is controlled either by valves or by volumes changes. In many respects the two type of machines are similar but in details of construction, operation and fields of application, they are quite different. Valves for flow regulation on one hand increases the flexibility in flow control on the other hand adds to the mechanical complexity of the system.

Stirling engines are regenerative engines where the flow is controlled by volumes changes. Machines where the flow is control by valves are called Ericsson engines. So far as is known, all the engines devised by Robert Stirling were of the closed-cycle type where the flow is controlled by volume changes, whereas John Ericsson produced both type of machines.

Stirling engines can be broadly classified into two distinct families which may be identified as: (a) single-acting or (b) double-acting engines.

Single acting engines are an ensemble of expansion space, compression space and associated heat exchangers in one or two cylinders with two reciprocating elements, one of which must be a piston. The other may be a piston or a displacer. Every ensemble constitutes a complete system which operates independently of any other single acting systems that may be coupled on a common crankshaft or other kinematic mechanism.

The Philips rhombic-drive engine, invented by R. Meijer, is an example of a single acting Stirling engine. Rhombic engines have been made in sizes ranging from miniature engines having output powers of a few watts to large engines of 100 horsepower per cylinder. They may operate as single-cylinder engines or in multiple units arranged in a common crankcase. A well known multiple-cylinder, rhombic-drive engine, was the Philips Type 4-235, four cylinder in-line, installed as the propulsion motor in a DAF bus.

Double acting engines are ensembles of multiple cylinders arranged such that the expansion space of one cylinder is connected through the associated heat exchanger to the compression space located in an adjacent cylinder. There is one reciprocating elements per cylinder, a piston-displacer. The great advantage of a double acting engines is that the number of the reciprocating elements is half the number required in a multiple arrangements of a single-acting machines. This means a simplified kinematic mechanism arrangement and so lower cost. The main disadvantage is the limited flexibility in design and to a lesser extent operating conditions

Design variants of single acting Stirling engines

All existing arrangements for the single-acting Stirling engine may be broadly classified into two groups: (a) two pistons machines, (b) piston-displacer machines. A further subdivision can be made in the latter group between machines in which the piston and displacer operate in a single cylinder, and those in which separate cylinders are provided. The principal distinction between a piston and a displacer is that there is a larger pressure difference between the upper and lower faces of a piston rather than of a displacer. Therefore, when reciprocating, the displacer does not work on the gas but merely displaces it from one side to the other. Figure 1 shows three basic arrangements by which most types of Stirling engines may be classified:

(a) Piston-displacer in the same cylinder

(b) Piston-displacer in separate cylinders

(c) Two-piston machine

Figure 2, instead, shows some of the possible alternative arrangements of single-cylinder piston displacer machines. One of the most interesting configuration is the free-piston Stirling engine, developed by William Beale.

The key identifying feature of any regenerative system is the manner in which the flow of working fluid is controlled. There are two possibilities; flow is controlled either by valves or by volumes changes. In many respects the two type of machines are similar but in details of construction, operation and fields of application, they are quite different. Valves for flow regulation on one hand increases the flexibility in flow control on the other hand adds to the mechanical complexity of the system.

Stirling engines are regenerative engines where the flow is controlled by volumes changes. Machines where the flow is control by valves are called Ericsson engines. So far as is known, all the engines devised by Robert Stirling were of the closed-cycle type where the flow is controlled by volume changes, whereas John Ericsson produced both type of machines.

Stirling engines can be broadly classified into two distinct families which may be identified as: (a) single-acting or (b) double-acting engines.

Single acting engines are an ensemble of expansion space, compression space and associated heat exchangers in one or two cylinders with two reciprocating elements, one of which must be a piston. The other may be a piston or a displacer. Every ensemble constitutes a complete system which operates independently of any other single acting systems that may be coupled on a common crankshaft or other kinematic mechanism.

The Philips rhombic-drive engine, invented by R. Meijer, is an example of a single acting Stirling engine. Rhombic engines have been made in sizes ranging from miniature engines having output powers of a few watts to large engines of 100 horsepower per cylinder. They may operate as single-cylinder engines or in multiple units arranged in a common crankcase. A well known multiple-cylinder, rhombic-drive engine, was the Philips Type 4-235, four cylinder in-line, installed as the propulsion motor in a DAF bus.

Double acting engines are ensembles of multiple cylinders arranged such that the expansion space of one cylinder is connected through the associated heat exchanger to the compression space located in an adjacent cylinder. There is one reciprocating elements per cylinder, a piston-displacer. The great advantage of a double acting engines is that the number of the reciprocating elements is half the number required in a multiple arrangements of a single-acting machines. This means a simplified kinematic mechanism arrangement and so lower cost. The main disadvantage is the limited flexibility in design and to a lesser extent operating conditions

Design variants of single acting Stirling engines

All existing arrangements for the single-acting Stirling engine may be broadly classified into two groups: (a) two pistons machines, (b) piston-displacer machines. A further subdivision can be made in the latter group between machines in which the piston and displacer operate in a single cylinder, and those in which separate cylinders are provided. The principal distinction between a piston and a displacer is that there is a larger pressure difference between the upper and lower faces of a piston rather than of a displacer. Therefore, when reciprocating, the displacer does not work on the gas but merely displaces it from one side to the other. Figure 1 shows three basic arrangements by which most types of Stirling engines may be classified:

(a) Piston-displacer in the same cylinder

(b) Piston-displacer in separate cylinders

(c) Two-piston machine

Figure 2, instead, shows some of the possible alternative arrangements of single-cylinder piston displacer machines. One of the most interesting configuration is the free-piston Stirling engine, developed by William Beale.